How can we be sure our PV solar modules and strings or arrays are working well? Referring to kWh or viewing the battery voltage is like driving with one eye open and not scanning enough. This article describes present practice and how we can determine how our solar modules are performing to give us clarity and knowledge they are generating the expected solar energy for our needs.

Present monitoring metrics

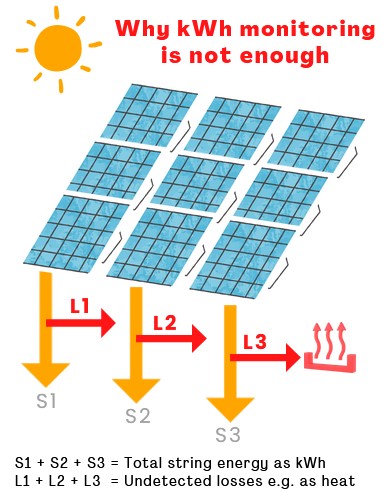

For most PV solar system owners, kWh or kiloWatt-hour is the only parameter available to know how much energy the system have produced to date and for indirect monitoring. Many PV owners install solar modules and the predominant monitoring parameter is kWh found in many inverter or charge controller apps. Some module level power electronics (MLPE) like micro-inverters or optimizers can also display individual module energy also in kWh. The reality is PV owners may not be harvesting the full energy due to preventable yet undetected solar generation losses. Let's uncover this.

Definition of kWh

According to wikipedia, the definition of the kilowatt-hour (kWh) "is a composite unit of energy equal to one kilowatt (kW) sustained for (multiplied by) one hour." What this means is a backward summation of power produced the past one hour. So if the smart meter reading frequency is 15mins, the kWh reading relates to past 4 readings summed up as kWh with solar generation of total kWh summed up for that day, month or year. Our utility billing process works using this cummulated kWh value times the prevailing rate to derive the monthly bill we are so familiar with. Most monitoring systems today use kWh as metric by design which simply measures the nett energy produced or consumed but does not determine how optimal our solar generation is.

Result: late discovery of any issue, slow indication of progress during troubleshooting and does not account for preventable losses from expected module specifications until much later.

Here's the bummer:

Most energy wastage arising from loose connections, to shading of modules from dirt, degraded cells etc almost always transform as heat. Short of doing an underside infra-red camera inspection of each module and cable lengths, the energy will not be discovered until it is significant for the kWh numbers from monthly bills do not add up from expected design value. An extreme scenario is the heat e.g. from arcing may pose as a fire hazard to both the PV system and even the building housing it!

We need a means to detect these energy drains early to minimize such wastage sources.

What is needed

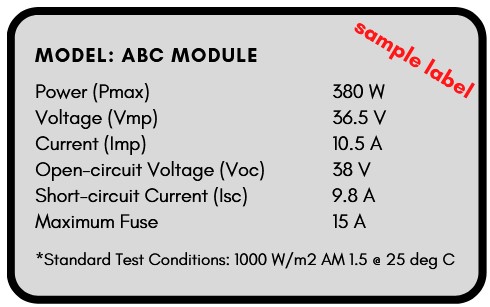

String testing based on module specifications will help. Each module is rated performance under Standard Test Conditions or STC. The information is reflected in label at back of each module in power, Voc, Vmp, Isc or Imp as shown in sample below. Each module can be tested via sun simulator facility or outdoor offline means using curve tracer. To disrupt the system to test each string or module even for a few minutes say once a year referencing to STC parameters is not practical and entails needless reconnection risks to system performance and test personnel.

How nice to have an uninterrupted means to assess each string at site during daytime.

PV owner can do as many times they want or periodically on scheduled frequency with results benchmarked to manufacturer's rated specification.

We have a solution

Soon to be launched product named as 'PVBuddy'. We wish to share with you how our test kit can help assess string of modules under outdoor on-site conditions without having to dismantle or disconnect the string. It will allow user to determine how healthy the string of modules is safely and easily so that you can be sure the modules are performing to manufacturer's specifications. With PVBuddy, you have the power to be sure!

Subscribe to be informed of the latest updates and product launches here.